1.8KW On Board Lithium Ion LFP Battery Charger

Here is the Charger designed for the LiFePO4 Battery Pack.

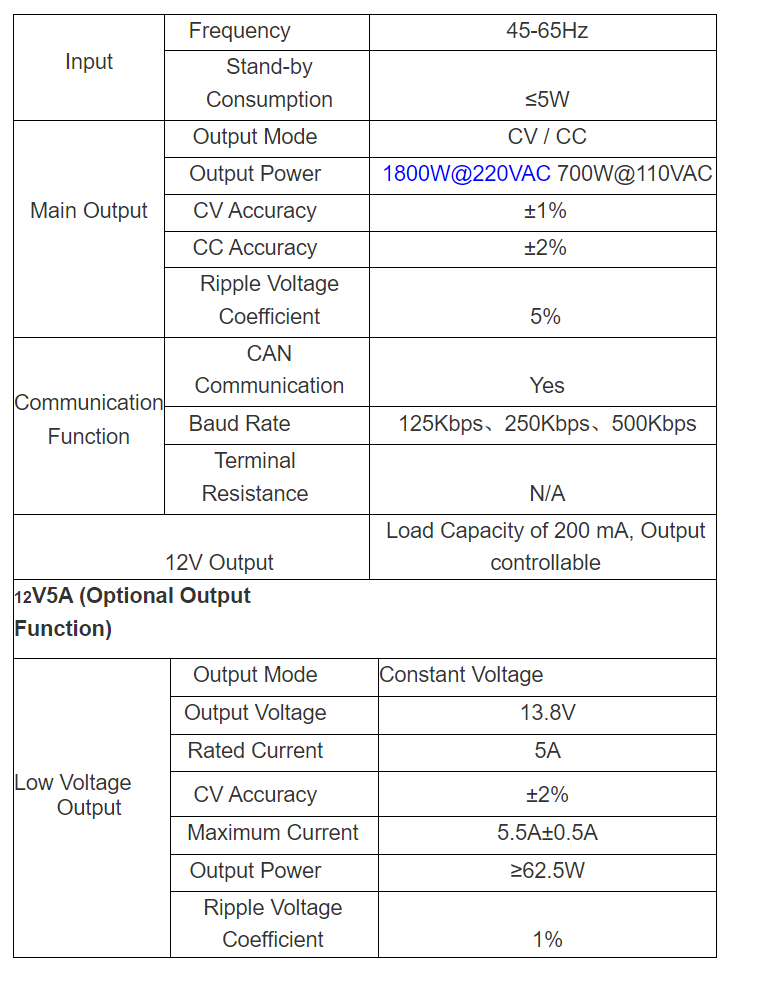

the power of the charger is 1.8kw

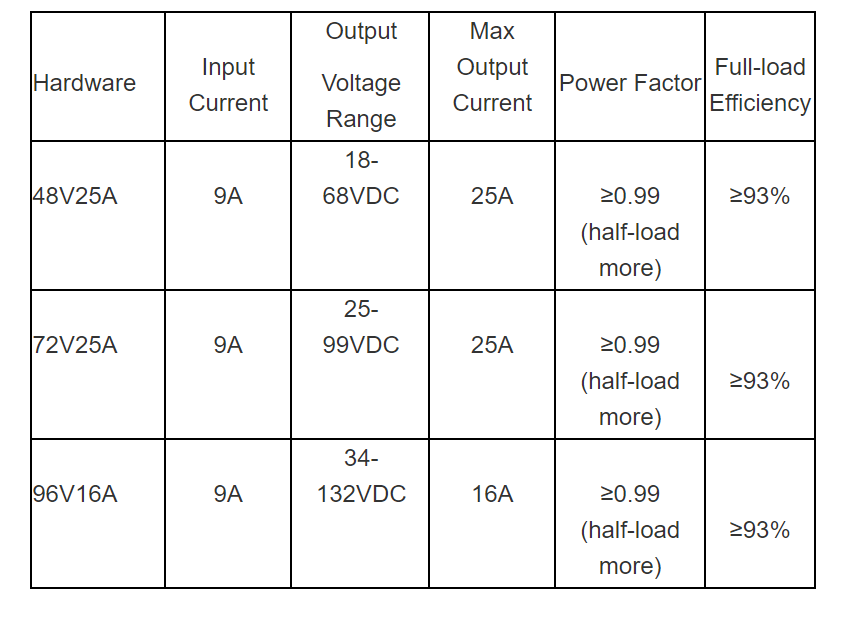

There are different modules of the charger

48V25A LiFePO4 Charger

72V25A LiFePO4 Charger

96V16A LiFePO4 Charger

The weight of the Charger is only 1.8kg. its one of the best Charger for your LiFePO4 Battery Pack

HK-H series 1.8KW charger was specially designed to supply electricity for electric vehicle’s power battery, on the basis of the national standards for the charger. This product has the advantages of not only only high efficiency, small size, high stability, long lifespan, but also high protection grade, and high reliability and complete protection function, etc. It’s definitely an ideal charging power supply for f electric vehicles.

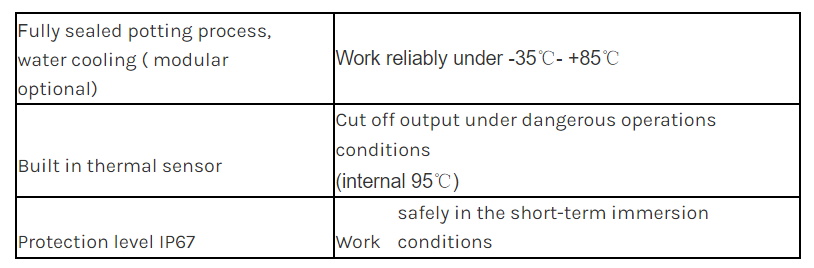

This charger has a built-in heat-sensing device and can automatically recover through the thermal protection. Fully sealed potting process and up to IP67 protection level ensures no trouble in any complex environment.

Key Feature

Essential parameter

Feature

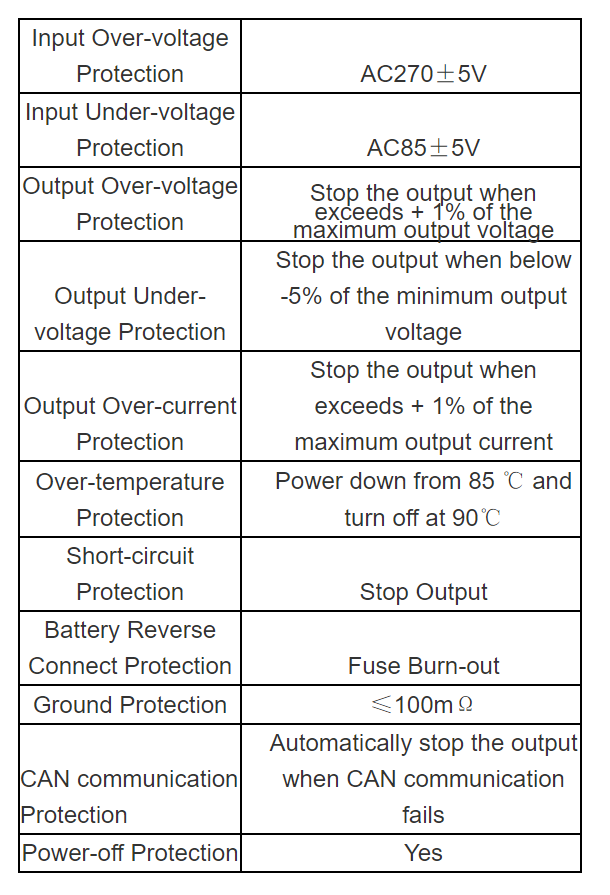

Protection Function

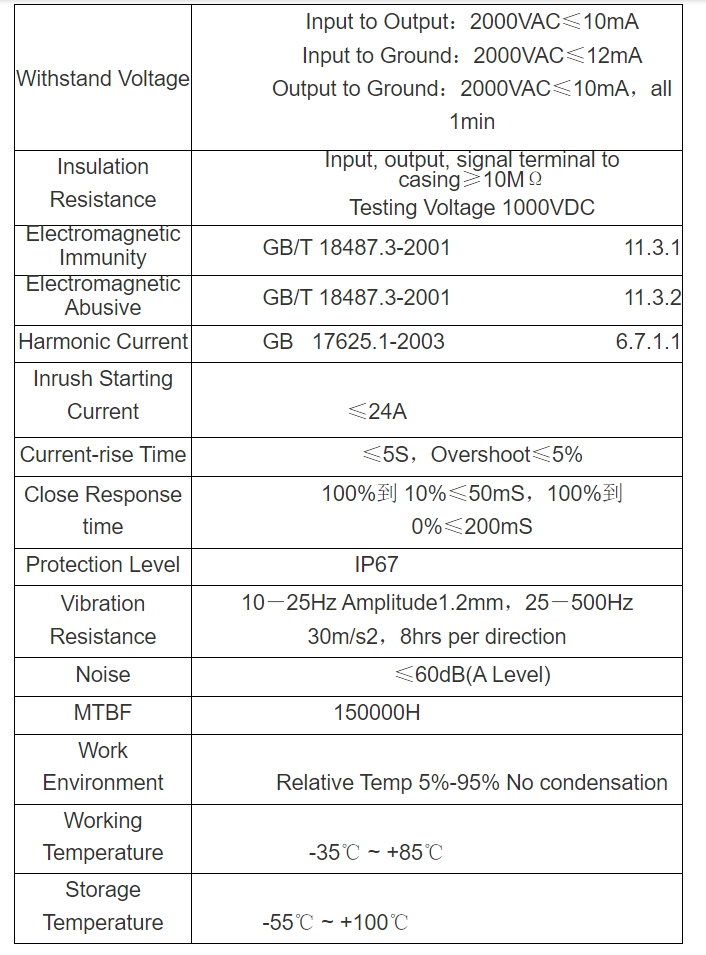

Safety and Others

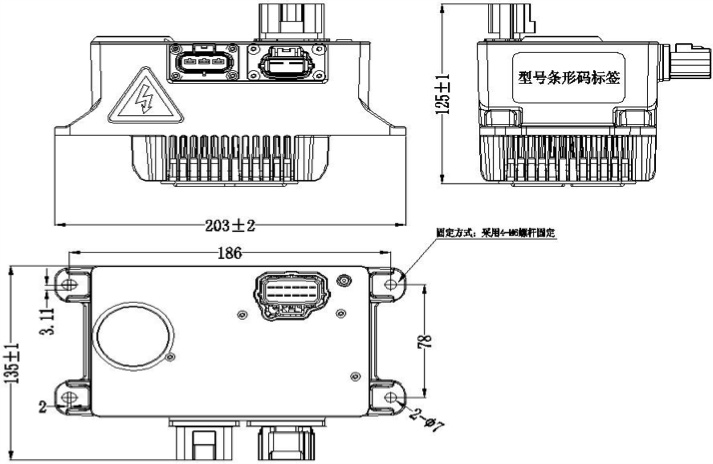

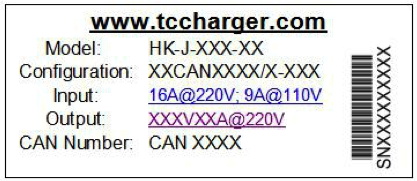

Installation size, label requirements and interface definitions

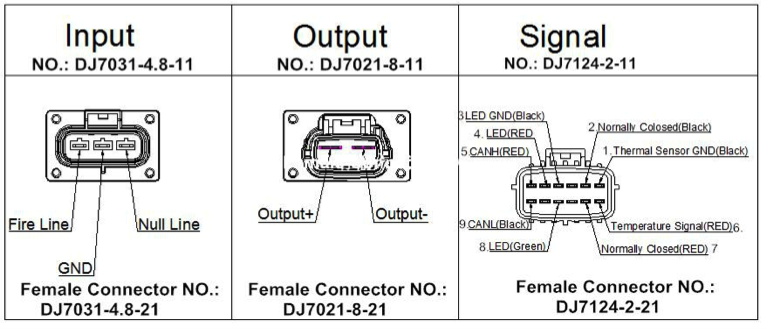

Interface Definitions

Charging Curve

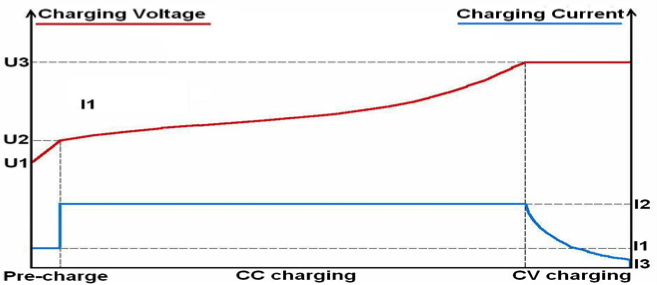

1). CC/CV Charging mode:(for Lithium Battery)

① Pre-charge:It only enters into pre-charging process when the battery pack voltage is under U2 ( The charger does not start when battery

pack is under U1), then it operates in a constant current charging I1, finally, the pre-charging process is completed when voltage rises to U2.

② CC Charging:It operates in a constant current charging I2, then the CC charging ends when voltage reaches to U3.

③CV Charging:Constant voltage charging with U3, the whole charging process is completed when current reduces to U3

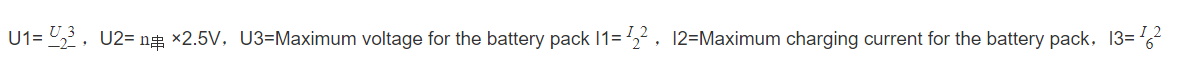

2). Different brand-name of lead-acid batteries have different kinds of charging curves.

Below shows a typical charging curve for Chilwee battery:

Expansion Function

Choose the accessories according to the actual needs: 1). Thermal Sensor Interface (for lead-acid battery charger)

Thermal Sensor is recommended to lead-acid battery charger, to detect the temperature of the battery and compensate charging voltage,

2). 12V Output

Charger provides a rating voltage 12V0.2A signal output. Its electrical connections is isolated from the interior circuit of the charger for

external application function extension. Note that this 12V with LED indicator output interface are common-grounded. The independent

12V output can supply power for the battery management system. Output 12V-5A.

3). LED Output Interface

Charger provides Red, Green two LED interface or Red, Yellow, Green three LED interface. Its electrical connections is isolated from

the interior circuit of the battery charger for external application function extension.

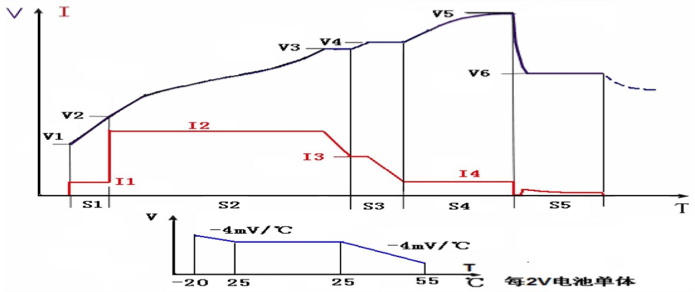

4). ENABLE Signal (for Lithium battery charger): External control circuit must be independent circuit

As for the lithium battery charger, it’s essential to use an enable signal to control the charger’s work or close. An isolated circuit (such as Relay

or Optocoupler) shall be adopted to control the charger’s work or close. Note that if the control circuit is not independent, it lead to

damage of the charger.

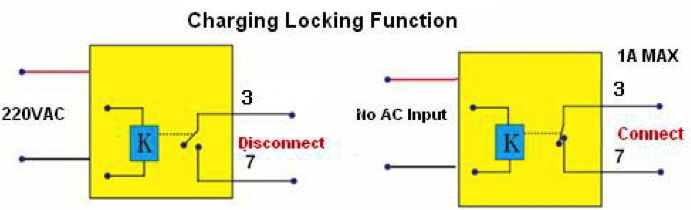

5). Charging Lock up Signal(for lead acid battery)

Charger provides a set of relay normally closed contact as charging locking signal output. When the charger has no electricity, the contact

connects, while the charger connects to the AC power supply, the contact disconnects immediately. The rated current of contact is 1A,

withstand voltage 30VDC / 250VAC.

Appearance Requirements

1). Outer surface should be smooth without obvious defects such as scratch, deformation. Surface coating should be uniform.

2). The nameplates and signs should be installed firmly with the neat handwriting.

3). Spare parts should be fastened reliably without rust, burrs, cracks and other defects and damage

4). Each product should be marked with product identification in obvious place, including part number, product brand, product type, production number, name of production enterprises, the warning message, etc

Packaging, Transport and Storage

1). Packaging

On the packing box, there are product name, product part number, product brand, product type, production number and name of

manufacturer; In packing box, along with the technical documents, it includes packing list, quality certificate, product specification.

2). Transportation

Suitable for cars, boats, aircraft, transportation. The products have to be prevented against sunshine and moisture and in a civilized

transportation.

3). Storage

Product should be stored in the packing box when it is not used and be maintained in a 5 ℃ to 40 ℃ clean, dry and well-ventilated

environment. It should not be stored together with chemicals, acid and alkali substances etc,. Should avoid storing in the sun, fire,

water and avoid storing with corrosive substances. The storage period is 2 years (from the inventory date of the factory). After the

2 years of storage period, the products should still comply with the provisions of the relevant standards.