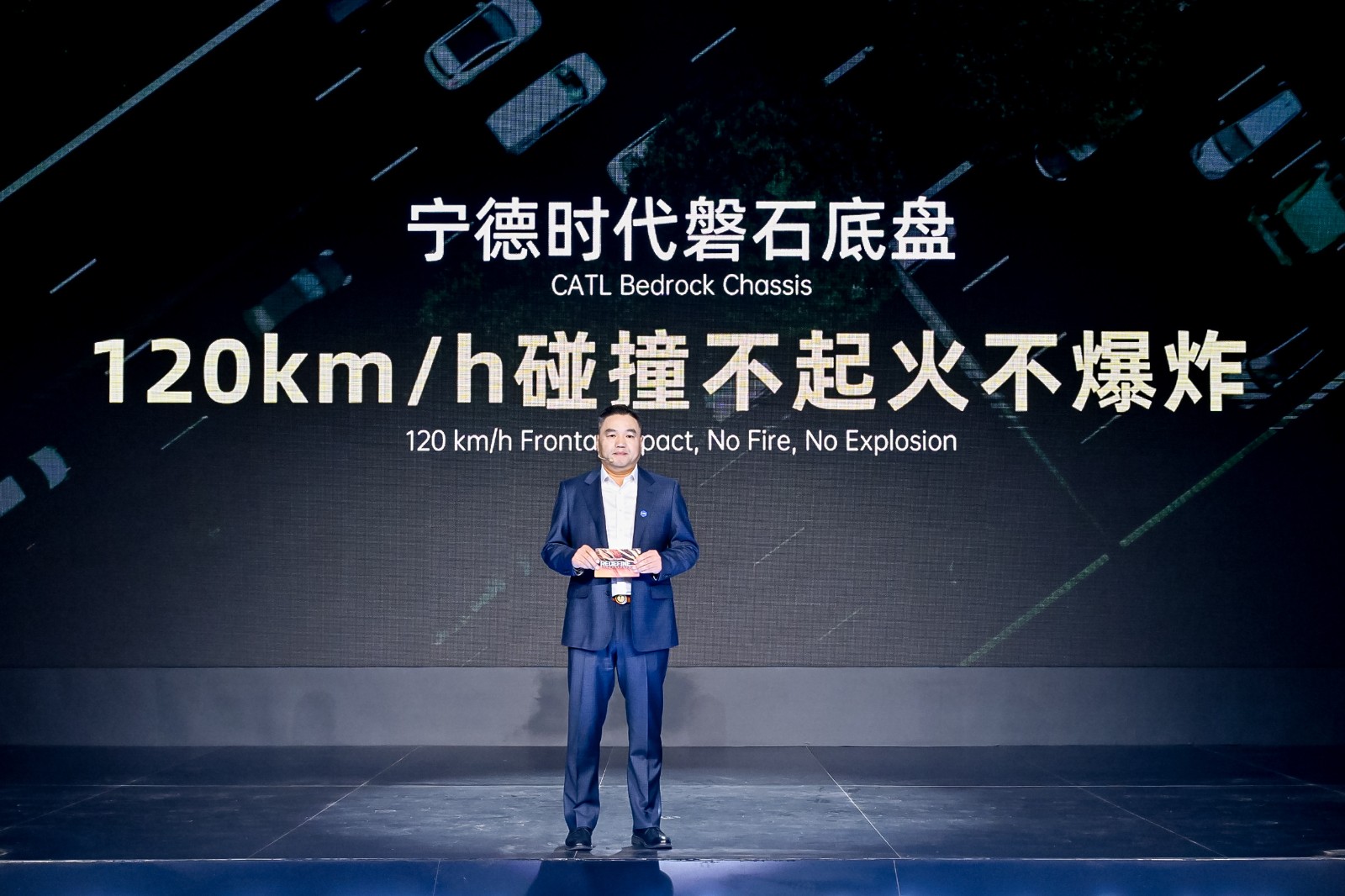

CATL Unveils Revolutionary Bedrock Chassis: A New Era of Ultra-Safe Electric Vehicle Design

On December 24th, CATL introduced its groundbreaking Bedrock Chassis, the world’s first ultra-safe skateboard chassis, setting a new benchmark for vehicle safety. This advanced chassis, engineered to withstand a 120 km/h frontal impact without catching fire or exploding, redefines what’s possible in terms of intelligent chassis safety, offering exceptional protection across various scenarios and speeds.

Leading the Way in Safety with Extreme Tests

The Bedrock Chassis incorporates a cutting-edge battery-centered design using Cell-to-Chassis integration technology, where the battery cells are directly integrated into the chassis. This design creates a unified structural framework that enhances safety while optimizing space. Additionally, by decoupling the chassis from the upper body, the Bedrock Chassis can absorb up to 85% of a vehicle’s collision energy—significantly outperforming traditional chassis, which absorb only about 60%.

CATL's Bedrock Chassis recently passed an unprecedented safety test, enduring a frontal central pole impact at 120 km/h—an extreme scenario that no new energy vehicle has attempted before. This dual extreme test, which evaluates both the highest speed and the strongest impact, proves that the chassis can survive such a collision without catching fire, exploding, or experiencing thermal runaway. In comparison, traditional industry standards, such as those in the China New Car Assessment Program (C-NCAP), test frontal impacts at just 56 km/h.

A frontal crash at 120 km/h generates collision energy equivalent to falling from a 56-meter-high building, a force 4.6 times greater than a 56 km/h impact. In more challenging pole crash tests, where the impact area is significantly smaller, the pressure on the chassis per unit area is 21 times higher than in traditional full-width frontal tests. Despite the extreme nature of these tests, the Bedrock Chassis has successfully withstood them, setting a new standard for vehicle safety.

A Leap Forward in Protection: Three Technological Breakthroughs

The CATL Bedrock Chassis incorporates three significant technological innovations that provide unparalleled protection across all driving conditions:

1. Biomimetic Tortoise Shell Structure: This innovative design integrates the vehicle’s body and energy unit framework, offering a "tortoise shell" effect that provides robust protection to the battery. This structure works in tandem with a specially designed aircraft carrier-grade arresting system that disperses impact forces through multiple pathways, gradually decelerating the vehicle and minimizing cabin intrusion during a crash.

2. Advanced Materials: The chassis utilizes high-strength materials, such as submarine-grade hot-formed steel (2000 MPa) and aerospace-grade aluminum alloy (600 MPa), which enhance rigidity and durability. These materials, combined with various barrier structures, make the chassis exceptionally resilient.

3. Ultra-Safe Battery Design: The Bedrock Chassis features a highly advanced battery design that includes NP technology and a high-ductility energy-absorbing insulation film. In terms of electrical safety, the chassis can disconnect high-voltage circuits within 0.01 seconds of impact and discharges any residual energy within 0.2 seconds—setting a new industry record for fast response times.

Revolutionizing Vehicle Development and Customization

The Bedrock Chassis is not only a technological marvel in safety but also a catalyst for transforming the automotive industry’s design and development processes. By offering a modular, customizable, and intelligent platform, the Bedrock Chassis accelerates the shift toward more personalized vehicle designs and reduces development cycles dramatically.

The chassis is designed with three key characteristics: internal integration, decoupling of the chassis from the upper body, and external openness. These features allow for flexible configurations, enabling automakers to build different vehicle models on a single platform. This reduces the time required for mass production from the traditional 36 months or more to just 12 to 18 months, greatly improving efficiency and allowing faster iteration of new designs.

Moreover, the Bedrock Chassis supports advanced intelligent systems, offering decoupling across mechanical, software, and electrical components. This enables the integration of L3 to L4 autonomous driving capabilities and provides a scalable, high-adaptability platform for future intelligent applications.

A New Era of Collaboration and Safety

At the launch ceremony, CATL also announced that AVATR, the first automaker to use the Bedrock Chassis, has entered into a strategic partnership with CAIT-SH, CATL’s skateboard chassis division. This collaboration aims to further enhance vehicle safety and offer a superior travel experience to consumers, reinforcing CATL's commitment to shaping the future of ultra-safe transportation.

With the launch of the Bedrock Chassis, CATL is not just pushing the boundaries of vehicle safety; it is activating a trillion-yuan market, accelerating the shift toward more sustainable, efficient, and intelligent automotive solutions. This marks the beginning of a new era in both safety and automotive design, one where ultra-safe, intelligent, and customizable vehicles become the new standard.