EVE Hydrogen Energy "Wukong" series AEM hydrogen production system leads the new future of the industry

In the context of the global energy transition, hydrogen energy, as a clean and renewable energy source, is gaining increasing attention. EVE Energy Co., Ltd., a global leader in new energy solutions, has recently launched its latest innovation, the "Wukong" Series AEM (Anion Exchange Membrane) Hydrogen Production System. This groundbreaking product not only signifies a significant advancement in EVE Energy’s hydrogen technology but also injects new momentum into the global hydrogen industry.

Overview of the "Wukong" Series AEM Hydrogen Production System

The "Wukong" Series AEM Hydrogen Production System represents a new type of hydrogen production technology, utilizing advanced anion exchange membrane technology to achieve higher hydrogen production efficiency and cost-effectiveness. Compared to traditional hydrogen production methods, AEM technology offers higher energy conversion efficiency, lower operational costs, and enhanced environmental friendliness.

1. Technological Principle

The core of the AEM Hydrogen Production System lies in the Anion Exchange Membrane (AEM), which separates oxygen and hydrogen ions in water and produces hydrogen gas through an electrolysis reaction. Compared to traditional Proton Exchange Membrane (PEM) electrolyzers, AEM technology operates efficiently at lower voltages, reducing energy consumption and operating costs.

2. System Features

· High Efficiency

The AEM Hydrogen Production System efficiently electrolyzes water to produce hydrogen and oxygen, achieving high hydrogen production rates.

· Cost-Effective

AEM systems use less expensive materials and have lower operating and maintenance costs compared to traditional PEM systems.

· Environmentally Friendly

The system operates without harmful by-products, meeting global environmental standards and contributing to the sustainable development of the hydrogen industry.

EVE Energy’s Technological Advantages and Innovations

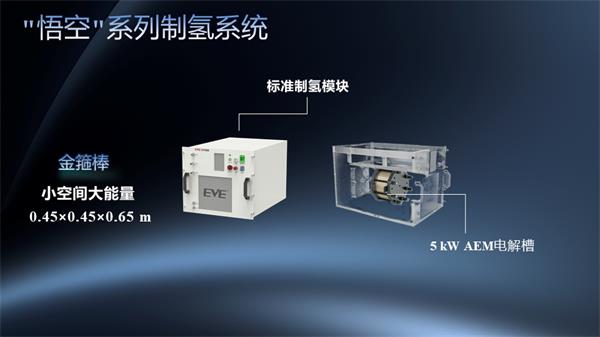

01 Ruyi Jingu Bang

—— Compact Size, High Power, Custom Configurations

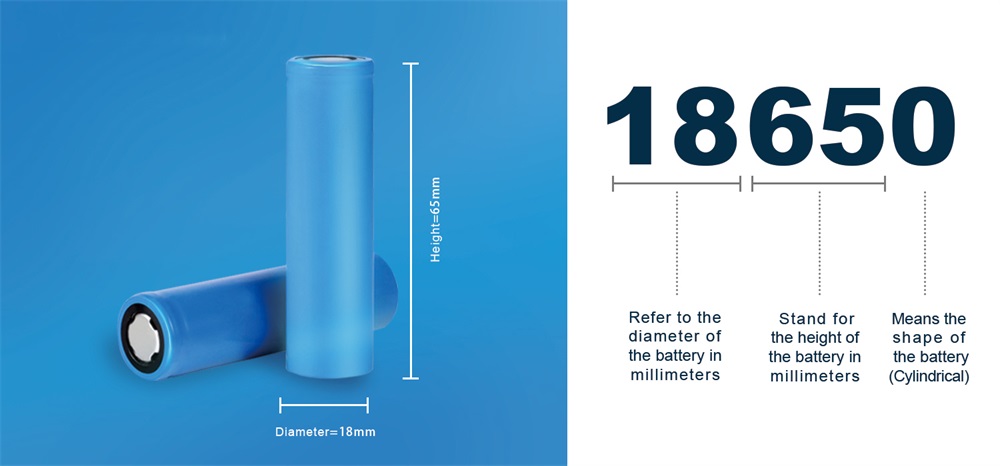

The core of the "Wukong" system is the hydrogen production module, which consists of a 5kW AEM electrolyzer and a Balance of Plant (BOP) system. It can operate independently with a 220V power supply and has a hydrogen production rate of up to 1 Nm³/h, while its dimensions are just 0.45×0.45×0.65 meters. Additionally, we have introduced a cabinet-type hydrogen production system that integrates the power system, water supply system, and drying system, achieving optimal resource allocation and intelligent management.

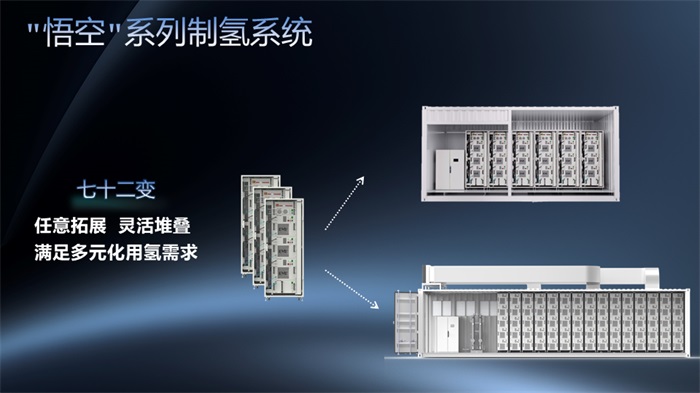

02 Seventy-Two Transformations

—— Flexible Expansion to Meet Diverse Needs

Building on the cabinet-type hydrogen production system, we have also developed a containerized hydrogen production system. This system features a centralized auxiliary system that efficiently integrates purification and water supply, while the hydrogen production modules can be flexibly stacked according to actual needs, accommodating hydrogen production requirements ranging from 1 to 200 Nm³.

03 Fire-Eye & Cloning Technique

—— Fault Detection to Prevent Downtime

Thanks to the modular design concept of the "Wukong" system, we have significantly reduced the economic impact of equipment failures on users. The clever modular stacking design means that both the cabinet and container types are divided into multiple independent operating units, fundamentally changing the traditional single electrolyzer structure where "one failure affects all."

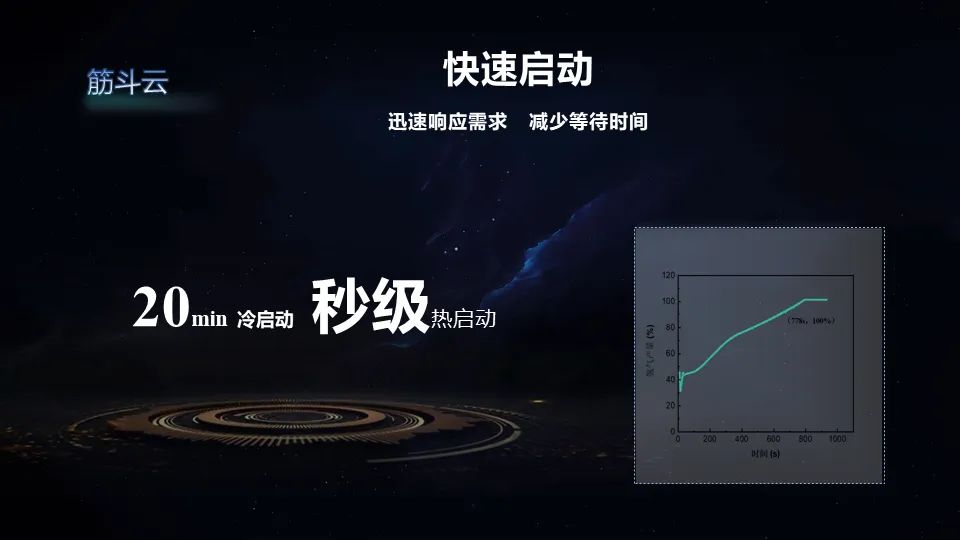

04 Nimbus Cloud

—— Rapid Start-Up to Maximize Green Energy/Off-Peak Energy Utilization

The "Wukong" system has demonstrated exceptional performance through rigorous testing. It reaches 100% load rating within just 20 minutes under cold conditions, and responds in seconds during a hot start. This unique advantage enhances the interaction between the equipment and power system, increasing the energy utilization rate of wind, solar, and off-peak electricity. For instance, in a distributed photovoltaic off-grid hydrogen production setup, with typical sunlight duration of 6-8 hours per day, the "Wukong" system can quickly reach its rated hydrogen production state, improving daily utilization hours by 0.5-1 hour, effectively acting as an "accelerator" for converting green energy into hydrogen energy.

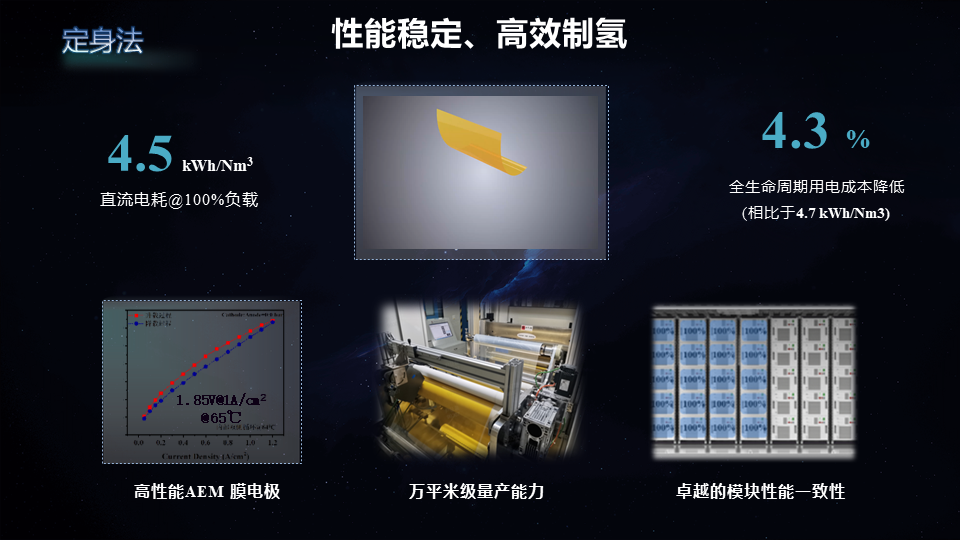

05 Body Fixation Technique

—— Stable Performance and Efficient Hydrogen Production

In addition to its remarkable rapid response capability, the "Wukong" system is equipped with high-performance AEM membrane electrodes developed and mass-produced by EVE Energy. The direct current energy consumption is as low as 4.5 kWh/Nm³. Supported by EVE Energy’s strong AEM membrane manufacturing system and extensive production capacity, the quality and continuous supply of the membrane material are effectively ensured. Consequently, compared to traditional high-energy-consumption hydrogen production equipment, the "Wukong" system significantly reduces the electricity costs over the equipment’s entire lifecycle.

Market Prospects and Application Scenarios

The release of EVE Energy’s "Wukong" Series AEM Hydrogen Production System marks a new phase in hydrogen technology development. Its market prospects are broad, with primary application scenarios including:

1. Transportation

Hydrogen fuel cell vehicles, as a clean energy transportation solution, require efficient and economical hydrogen production systems. The "Wukong" Series can provide stable and efficient hydrogen supply for this market.

2. Industrial Applications

In sectors such as fertilizers, metallurgy, and petrochemicals, where hydrogen is a crucial raw material and reducing agent, the demand is substantial. The "Wukong" Series AEM Hydrogen Production System offers a reliable solution for these industries.

3. Distributed Energy

With the rise of distributed energy systems, there is a growing demand for small-scale, efficient hydrogen production facilities. EVE Energy’s "Wukong" Series can meet this demand and support the development of distributed hydrogen energy applications.

EVE Energy’s Strategic Layout and Future Outlook

EVE Energy’s ongoing innovation in hydrogen technology reflects its global strategic layout and foresight in the future energy market. The company will continue to promote and apply the "Wukong" Series AEM Hydrogen Production System, aiming to make this technology a core pillar of the global hydrogen industry.

Looking ahead, EVE Energy plans to expand its presence across the hydrogen industry chain, including hydrogen storage, transport, and refueling infrastructure, to create a comprehensive hydrogen energy ecosystem. The company will also deepen its international market partnerships to drive global application of hydrogen technology.

Conclusion

The launch of EVE Energy’s "Wukong" Series AEM Hydrogen Production System is a significant milestone in the development of hydrogen technology. With its efficiency, cost-effectiveness, and environmental benefits, this technology will have a profound impact on the global hydrogen industry. EVE Energy will continue to drive innovation and advance sustainable development in the energy sector, paving the way for a cleaner and greener future.