Towards independent innovation: Power battery from VDA, MEB to short knife

In the early 1990s, China formulated the "market for technology" foreign major industrial economic policy, hoping to rely on the introduction of foreign investors to achieve industrial technological progress, which can be summarized by the "three-stage" logic: First, introduce foreign advanced technology, then digest to achieve localization, and finally achieve independent development, the author's first job after graduation is to introduce German light industrial machinery for digestion and absorption.

However, the practice of 40 years of industrial development reform and opening up has proved that if there is no independent innovation, no enterprise and industrial sector can go through these three stages, resulting in giving up the market but not in exchange for technology. For example, in the automobile industry, although it has been requiring independent development, some of the car companies on the road to joint ventures, do is to pull the appearance of foreign eliminated models to change the brand, and sometimes even bother to pull the brand, only change the trademark on the domestic market.

On the contrary, in the past decade, with the opening up of the market and the rise of pure electric vehicles, there has been a new car manufacturing force, and China's car industry has officially embarked on the road of independent development. The development of power batteries as the core components of pure electric vehicles typically relying on independent research and development and innovation, which has made the world's most complete industrial chain and the largest production and sales industry, not only the first and second place in global production and sales, but also six or seven Chinese enterprises in the top ten.

From the perspective of the evolution of the square power battery structure, this paper tries to explain that independent research and development and innovation is the only way for China's industry to catch up and even surpass, which is a reference for industry chain practitioners, enterprise management research institutions, innovation and entrepreneurship research institutions, and government policy research departments.

The predecessor of the square battery is this life

Looking back at the history of the development of square batteries, the earliest origin can be traced back to Japan.

In the early days, when lithium-ion secondary batteries were just commercialized and packaging forms blossomed, the shape of square batteries had already appeared, but due to the early use of steel shells, the advantages of specific energy were difficult to play, and the market recognition was not high.

In 1995, Sanyo Electric launched a square lithium battery with an aluminum alloy shell, which is about 30% lighter than the steel shell. Due to their lightweight, regular shape and high space utilization rate, square batteries are gradually used to replace cylindrical batteries in 3C fields such as mobile phones and laptops, but they are gradually replaced by soft-pack batteries due to the extreme demand for thinness and lightness of smart phones. After Sanyo was acquired by Panasonic, the square battery was shelted by Panasonic after the small supply of hybrid models of Toyota, Volkswagen and Ford, and then it focused on the cylinder battery route bound to Tesla.

It is easy to understand that at that time, the cylindrical battery has formed a series of international unified standard specifications and models, the process is mature, the cost is optimized, the manufacturing technology was leading, and it was suitable for large-scale continuous production, and the production difficulty of the square battery with more specifications and models and immature process is much lower. At that time, the square battery could not fight against the cylindrical battery.

Square batteries enter the field of automotive use

In the automotive field, square batteries almost enter at the same time as cylindrical batteries, but there is no well-known car companies and models such as Tesla, and the popularity of square batteries is not high at the beginning.

In 2008, BMW began to layout new energy, in the global investigation and selection of power battery suppliers, the Germans are open to all kinds of batteries, but in the trial stage to hold a basic bottom line, that is, everything must make way for safety. The Germans believe that to minimize the safety risk of the power battery, it is necessary to develop and design products at the car gage level, and finally introduced the specific program of A-B-C-D four sequence samples.

The compact structure and high space utilization of the square battery made them finally choose the square battery. Samsung SDI seized the opportunity to cooperate with BMW to launch the BMW i3 prototype Megacity with square batteries in 2009, and Samsung successfully entered the BMW supply chain to supply square batteries for BMW i3, i8, and iX series models. After the BMW i3 was sold worldwide, the square battery was able to successfully open the power battery market.

VDA and MEB standards launched in Europe

The VDA, short for "Federation of the German Automotive Industry", is an association of more than 600 Oems and suppliers from the German automotive industry (Quality Management Center of the German Automotive Industry Federation), which aims to research and produce clean and safe vehicles for the future. Support the development of the German automotive industry through specific activities in the areas of economy, transport, environmental policy, technical legislation, standardization and quality assurance.

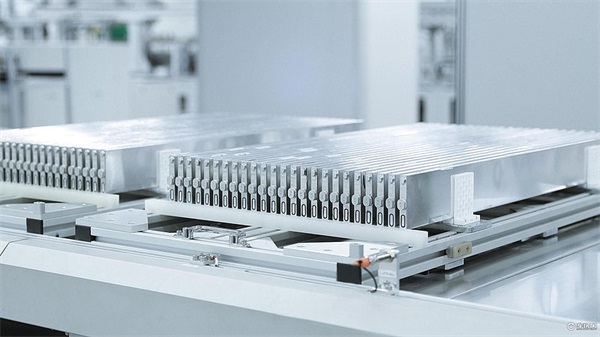

VDA battery standard size launched around 2012, in fact, is a series of unified module standards, whether the cell is cylindrical or soft bag, square, first made into a unified standard module, to design and repair replacement. The proposal of the standard module is the result of the continuous game and exploration of the upstream and downstream of the industry, since its launch, the VDA standard has been verified in Europe for many years and has also been widely used in BMW, Volkswagen and other brands.

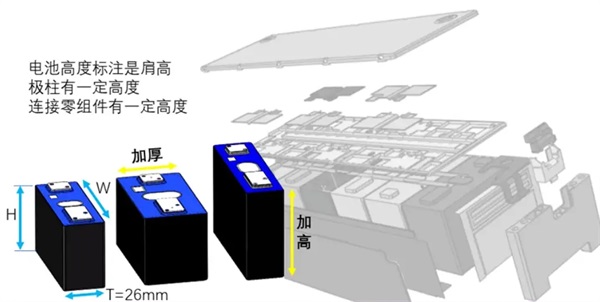

The VDA cell standard size "355 modules" is named based on a single module length of 355mm. This module is also the most widely used module specification in China. Ningde era is the first from the VDA355 module to develop the use of different thicknesses of the cell (1 times, 1.5 times, 2 times, 3 times thick), its demonstration effect and rapid development makes this standard square cell fully promoted and applied.

Considering the insufficient space utilization of the vehicle using 355 modules (3 rich, 4 can not be put in), the "390 modules" appeared.

In 2018, Volkswagen announced its full entry into electrification, launched the modular electric drive platform MEB and opened the "590 module" used by MEB to other car companies. This representative module can be said to be designed based on many common technology platforms, which can greatly reduce costs and improve production efficiency for Oems and power battery manufacturers.

The development of the Chinese market has led to an era of leapfrogging from oil to electricity to positive design of new models

The entire year of 2023 can be estimated to sell nearly 9 million new energy vehicles, we based on this data insight into what happened in the market.

According to the data of "2023 China Automobile Replacement Consumption Insight", among the replacement choices of consumers, the choice of sedan decreased by 17.6%, SUV increased by 15%, and MPV increased by 2.6%; SUV owners have the highest loyalty, basically just changing to a larger SUV, because the family is generally a major node of the family to buy a car, get married or have children and two children. In recent years, China's SUV market is popular and major car companies have launched a round of new car competition for this, fortunately, these new models have abandoned the old platform of oil to electricity, and adopted a new design and new platform, which is not compatible with the original design of European car companies.

Compared with the early days of new energy vehicles, the voltage platform has also changed, and even began to go on the 800V platform.

Compared with the European market in the early stage, the terpolymer system is the mainstream, and China's mainstream is equipped with lithium iron phosphate cells, which requires higher volume space utilization efficiency.

Byd started from the battery into the car, and BYD car uses of lithium iron phosphate battery, so it does not follow the favorable three-way German VDA standard, its battery design from the beginning considers the battery and vehicle matching, cell size beyond the same period of other battery companies. For example, the PHEV cell size of BYD's F3DM launched in 2008 is 356*100*28mm, which has exceeded the size of the late VDA EV(173*115*45mm), and the pole leading direction is different from the VDA, but respectively from the small sides of both ends.

As can be seen from the size of BYD's power battery, the basic idea is to make the cell long and thin, and lead the pole from the smallest two faces. This idea later formed BYD's main push-blade battery.

Starting from BYD, Chinese car companies based on independent research and development and market positioning, demand is different and other reasons, and did not go in the direction of the European VDA/MEB platform module, but began to walk out of the power battery road with Chinese characteristics.

The short blade goes to the front of the platform

Although the model is different, the chassis position available for battery installation in each car is common. Under the principle of maximum space utilization, there are only a limited number of possibilities for the size and placement of the module: center aisle, under the front seat, under the rear seat, under the trunk of the luggage or between the two wheels above the rear axle, then: 1, the Z height space of the battery cell is limited to 110mm, in order to reduce the wind resistance of the vehicle, it is best to leave the capacity, wiring on both sides, and the side pole; 2, based on a specific platform, expand several models, based on the short-knife battery cell structure to meet the maximum common battery layout, the length of the battery size specification is 300mm/ 400mm/ 600mm, the height is customized from the chassis space of the platform under the model to 92~120mm, the thickness is within VDA26mm, The thinner size is adjusted for various capacity changes.

In the past two years, the PHEV market has risen rapidly, carrying 10 to 40 degrees of electricity, the battery pack is small, and the space needs to be effectively used, and the battery cell of L400 has been widely welcomed by car companies. L400 with flexible size and high energy density, the corresponding PHEV battery pack can also use CTP structure, volume utilization is improved, higher power, longer battery life.

In the announcement of batch 372, the number of new energy passenger car models supported by Svolt reached 12, including 8 PHEV models. In the 373 batch announcement, Svolt respectively provides battery support for 8 new energy passenger car models of Great Wall, Ideal, Geely, Lantu and other car companies, of which PHEV accounts for 6, fully showing its popularity in the plug-in market.

It is precisely because of the fit problem of the model that BYD actually uses a short blade on the plug-in model. For example, the BYD Qin DMI model uses a 240mm length battery cell, and the Tang DMI uses a 152mm length battery cell, rather than the long blade advertised in the early days.

The CATL also has a trend toward long and thin progress, for example, the size of a battery cell is 300*117*27mm, which is more like a shorter blade, but the pole is still the top side.

Svolt innovative short blade category has established its market position earlier than the cylindrical 4680 series and has been widely accepted by domestic and foreign car companies. A series of friends are following the short blade category to design new products, I believe that the shape of the short blade is becoming the mainstream shape of the square cell, and even is expected to become the ultimate form of the square power cell.

finally

Rooted in the market, explore user needs, bold forward research and development, and independent innovation, it is possible to create a 50/50 world of heavy equipment, in the power battery development practice, the experience of positive design to produce benefits is worthy of appreciation.

The new era, the new journey, the sea of stars of scientific and technological innovation, make our hearts surging. In this century of unprecedented changes, do not sit idly by, boldly bow into the situation, quite responsible, let the light of life shine in this ever-changing era stage!