Tesla 4680 Battery Material Innovations

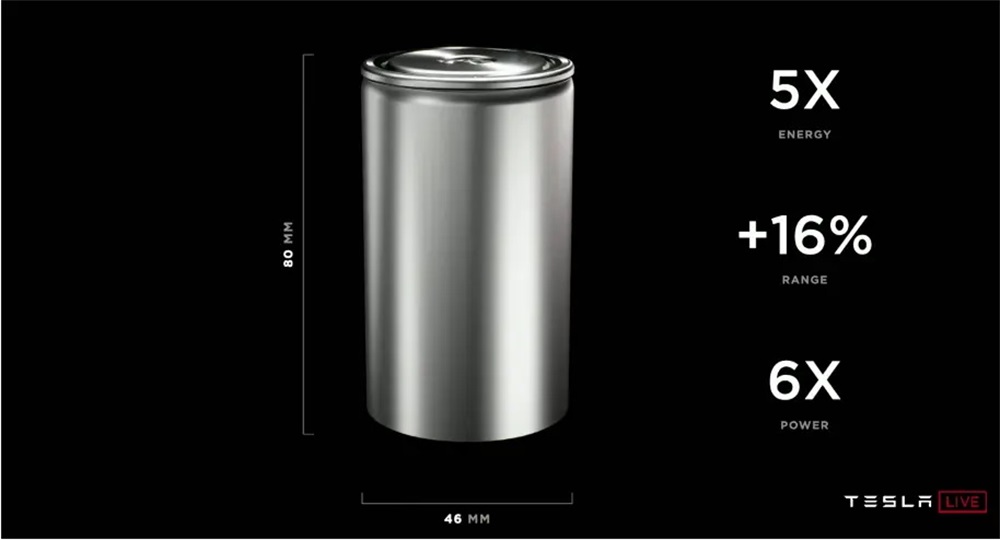

What is a 4680 battery?

The 4680 battery is a new generation of cylindrical batteries with a diameter of 46mm and a height of 80mm introduced by Tesla.

1) Ultra-high Nickel Multicomponent Cathode: NCMA (Nickel-Cobalt-Manganese-Aluminum) Ternary Material

The NCMA material increases nickel content while maintaining cost reduction and material stability. In China, the high-nickel cathode market is relatively concentrated, with CR5 achieving 86.4%, and companies like Changcheng Technology (当升科技) leading the field.

2) Silicon-Carbon-Silicon-Oxygen Anode

The theoretical maximum capacity of silicon can reach 4200 mAh/g, more than 10 times that of graphite. Currently, the mass production capacity exceeds 400 mAh/g. Domestic companies like Sungrow (杉杉股份) and BTR New Energy (贝特瑞) are leading in the mass production and supply of silicon-based anodes.

3) Single-Walled Carbon Nanotube Conductive Additives

Carbon nanotubes help alleviate the expansion issues of silicon anodes, improving cycling performance, reducing electrolyte loss, and enhancing lifespan. Single-walled carbon nanotubes are more effective. Tian Nai Technology (天奈科技) is actively developing related products.

3.1 Silicon Anode

3.1.1 Advantages

1. Higher Theoretical Energy Density

Graphite anodes have a theoretical maximum energy density of 372 Wh/kg, while silicon anodes can achieve up to 4200 Wh/kg.

2. Better Safety

Silicon’s voltage platform is higher than graphite, reducing the risk of lithium dendrite formation. Dendrites can puncture the separator, leading to short circuits between the positive and negative electrodes, which is a safety hazard for batteries.

3. Lower Cost

Silicon is abundant, cost-effective, and environmentally friendly. The use of silicon anodes can increase the mass energy density of lithium-ion batteries by more than 8%, increase volume energy density by over 10%, and reduce the cost per kilowatt-hour by at least 3%.

3.1.2 Disadvantages

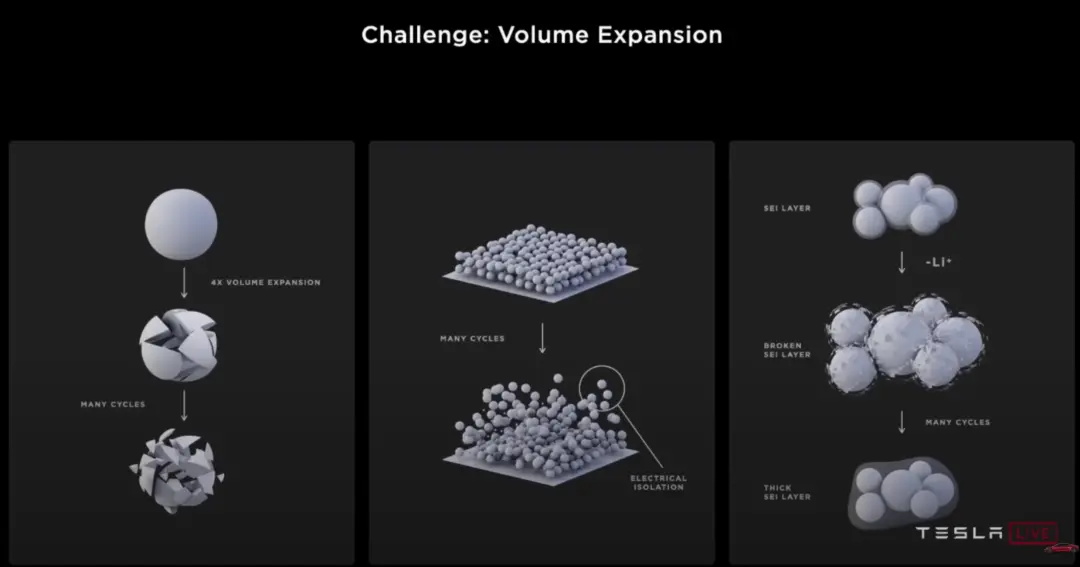

1. Poor Cycling Performance

Silicon expands more than four times its original volume when lithium ions are intercalated, which causes degradation of the battery after several cycles of expansion and contraction.

2. Poor Conductivity

Silicon has low electrical conductivity, which limits its full utilization and performance. The volume changes result in poor contact between the active material and conductive additives, decreasing the conductivity. The thick and uneven SEI (solid electrolyte interface) layer on the silicon surface also affects conductivity and the overall energy density of the battery.

3.1.3 4680 Battery Innovation Design

※ Tesla silicon anode process principle

Tesla has redesigned the raw materials, using highly elastic materials and adding elastic ion polymer coatings to stabilize the silicon surface structure, thus reducing costs by 5%.

3.1.4 Silicon-Carbon Anode as the Future Direction of Silicon Anodes

Battery companies are actively adopting silicon-carbon anodes: Currently, silicon-carbon anodes are mainly used in cylindrical batteries, with companies like CATL, BYD, Gotion High-tech, and Pride using them in high-capacity battery solutions. The trend toward silicon-carbon anodes is clear.

With rapid development in the silicon-carbon industry, Chinese companies are catching up with international players. Domestic anode manufacturers, including BTR, Sungrow, Gotion High-tech, and Zhengtuo Energy (正拓能源), have already achieved mass production. BTR supplies silicon-carbon anodes to Panasonic for use in Tesla’s battery supply chain. Several other battery manufacturers, such as CATL, BYD, Gotion High-tech, Pike, and Tianjin Lishen, are also actively investing in silicon-carbon development.

Silicon-carbon batteries represent the inevitable trend toward high energy density. As technological bottlenecks are overcome and end-user acceptance grows, silicon-carbon will become more cost-effective and achieve large-scale mass production. CNCET predicts that China’s silicon-carbon anode production and consumption will reach 60,000 tons in 2023, with a massive market potential in the future.

3.2 Cathode

Different cathode materials are used in different products:

· The iron phosphate version of the 4680 battery is used in low-range vehicles and energy storage systems, prioritizing longer cycle life.

· The nickel-manganese-lithium (NCM) version of the 4680 battery is used in mid-range vehicles and home batteries.

· The high-nickel 4680 battery is used in products like the Cybertruck and Semi.

Tesla's cathode materials focus on high-nickel, cobalt-free directions, but no significant innovations beyond mainstream approaches have been proposed. Tesla uses NCA (Nickel-Cobalt-Aluminum) single-crystal cathodes, increasing voltage to boost energy density while achieving thermal stability comparable to lithium iron phosphate (LFP).

3.2.1 NCA (Nickel-Cobalt-Aluminum)

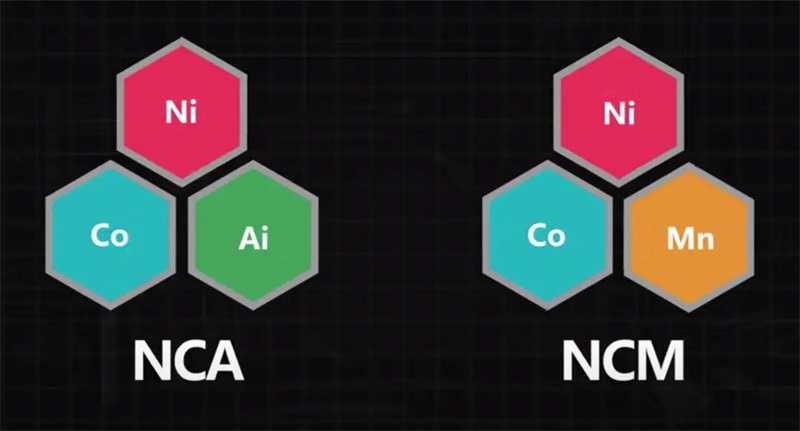

There are two main types of ternary cathode materials:

1. Tesla uses NCA (Nickel-Cobalt-Aluminum)

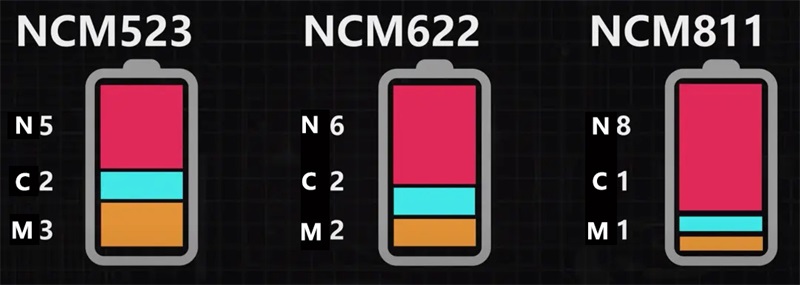

2. Others, like CATL, use NCM (Nickel-Cobalt-Manganese), such as NCM523, NCM622, NCM811.

※ Differences Between NCM and NCA

· Nickel: Enhances energy density and lowers cost, crucial for increasing battery range.

· Cobalt: Provides structural strength for the cathode, but is expensive and environmentally harmful.

· Manganese and Aluminum: Improve heat conduction and thermal stability, which are key for safety.

· Iron: A potential replacement for nickel, cheaper but offers lower energy density and higher charge/discharge cycles.

Compared to NCM, NCA has a higher energy density but requires more precise manufacturing, and its safety is slightly lower. Tesla increases nickel content and reduces cobalt to enhance energy density and reduce cost.

※ Cobalt content in NCM is gradually decreasing

3.2.2 Single-Crystal Technology

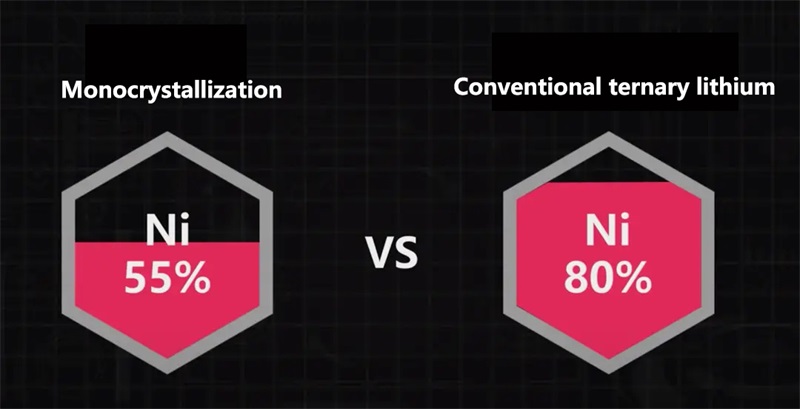

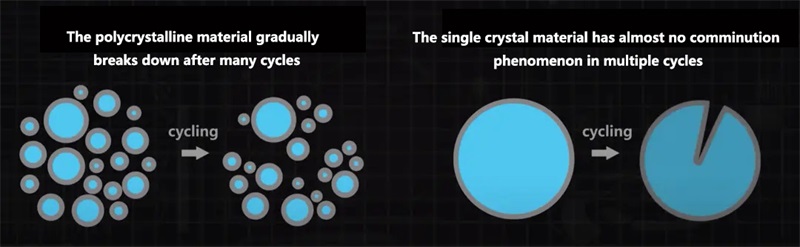

While increasing nickel content boosts energy density, single-crystal technology enhances energy density by increasing the voltage of the cathode material. Single-crystal materials are more suited for high-voltage applications, as they lack grain boundaries, improving both thermal battery stability and cycling performance.

※ Monocrystalline positive nickel content

※ Single crystallization improves battery cycle performance

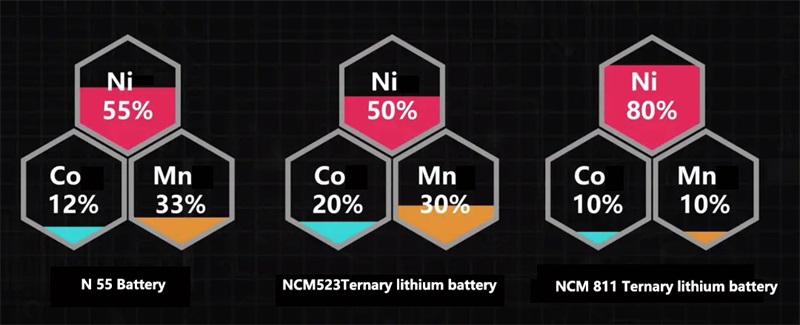

For example, Nickel-55 single-crystal batteries, which have the same nickel content as NCM523, achieve the energy density of NCM811 while offering better thermal stability and lower cost.

※ Comparison of Nickel-55 and NCM Batteries

3.2.3 4680 Battery Cathode Trends

The 4680 battery uses three types of cathodes:

1. Iron Phosphate (LFP)

2. Nickel-Manganese-Aluminum (NCM)

3. High-Nickel

a) High-Nickel 4680:

Tesla currently focuses on high-nickel 4680 batteries, which are used in high-range models like the Cybertruck and Semi. High-performance versions of Model 3 and Model Y may also use this type of battery.

b) Nickel-Manganese 4680:

After the high-nickel version becomes mainstream, Tesla plans to develop the 4680 nickel-manganese version, which will be used in mid-range Model Y and home batteries.

c) Iron Phosphate 4680:

Tesla might also introduce an iron phosphate version of the 4680 battery. Although the company did not mention its cycle performance in its battery launch event, it’s expected that the iron phosphate version will be introduced after the nickel-manganese version matures. This type of battery would be used in lower-priced vehicles and energy storage systems, focusing on higher cycle life.

The progression of 4680 battery models—from high-nickel to nickel-manganese, and eventually iron phosphate—will drive demand for relevant materials.