Power battery 6C Era: CATL Launched the Industry's First 6C Ultra-fast Charge Lithium Iron Phosphate Battery

On September 25, SAIC General Motors announced that it launched the industry's first 6C ultra-fast lithium iron phosphate battery(LFP BATTERT) with CATL.

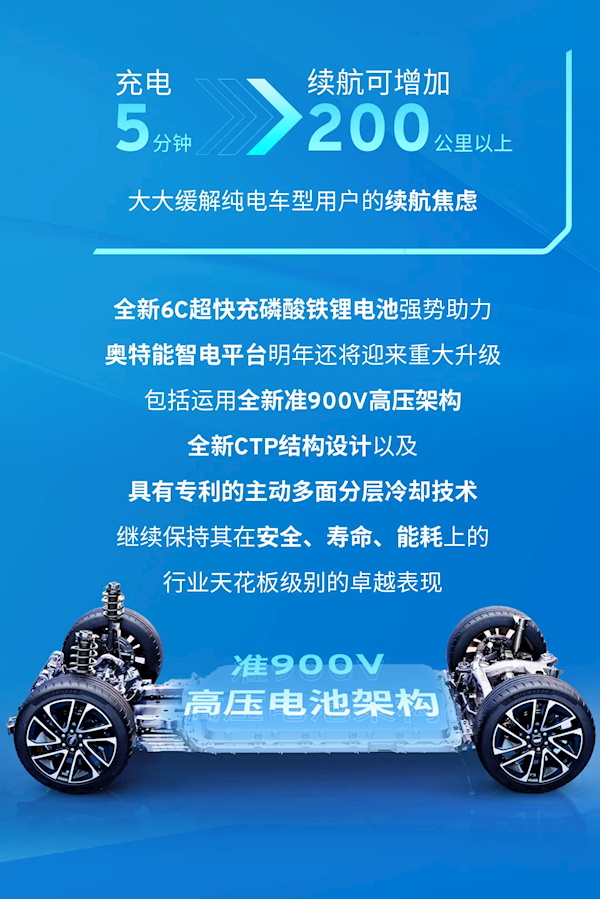

Saic-gm said that the new products will be put into use next year on the newly upgraded AoTE quasi-900V high-voltage battery architecture to unlock a more efficient and convenient fast charge experience.

Here we relate to the electric vehicle industry often said "several C" battery, a measure of charging speed, refers to the battery in the specified time to charge to its rated capacity required current value, the general charging rate is expressed by C.

Charging ratio C = charging current (A)/ battery rated capacity (Ah), the higher the charging ratio, the faster the battery charging and discharging speed.

C as the battery charging ratio, 6C means that the battery can be fully charged in one-sixth of an hour, that is, 10 minutes. The fast-charging battery uses lithium iron phosphate cathode material, which is the most mainstream technical route for domestic power batteries.

At present, a number of domestic car companies have released 5C supercharged batteries, but with the faster 6C supercharged batteries, few car companies announced their product planning. CATL launched the industry's first 6C ultra-fast charge lithium iron phosphate battery, which is a combination of multiple atomic levels of fast charge technology in the battery field. Including superelectronic net positive electrode technology, the second generation of graphite fast ion ring technology, ultra-high conductive solution formula, nanoscale ultra-thin SEI solid electrolyte interface film, optimized high porosity isolation film, etc. It fully demonstrates its core innovation capabilities and is a new benchmark for the industry

Leading technology advantage to achieve super-fast charging

1. In terms of the positive electrode technology of the super-electronic network, the battery uses the fully nano-sized lithium iron phosphate material to build a four-way super-electronic network, thereby improving the electrochemical reaction efficiency, enhancing the charging efficiency, and ensuring the stability of the battery performance.

2. In the second generation of graphite fast ion ring technology, the battery is equipped with multi-gradient layered pole plates to build a "highway" of current conduction, significantly reducing charge and discharge time, and achieving higher energy density and higher cycle stability.

3. In terms of ultra-high conductive solution formulation, the battery effectively improves the conductivity and reduces the viscosity of the electrolyte, enhances the desolvation ability of lithium ions, and greatly improves the conductivity, electrochemical stability and safety of the battery cell.

4. In terms of nanoscale ultra-thin SEI solid electrolyte interface film, the internal resistance of the battery is reduced, the charging power and efficiency are improved, and the heat generated during the charging and discharging process is less, and the thermal stability is improved.

5. In terms of the optimized high-porosity isolation film, the battery through the high porosity, low tortuous pore, so that the lithium ion liquid phase transmission rate improvement and upgrading, for the charging speed has brought a qualitative leap.

Based on this, the 6C ultra-fast charging lithium iron phosphate battery can be charged for 5 minutes on the ultra-fast charging pile, and the battery life can be increased by more than 200 kilometers, which greatly alleviates the battery life anxiety of pure tram users.

The first 6C fast charge lithium iron phosphate battery will be shipped next year

Saic GM did not disclose the first model of the fast-charging battery and the range of the model. CATL did not immediately respond to a request for information about the battery.

The power battery usually adopts the assembly mode of cell - cell-module- - battery pack. Interface news learned from informed sources that the battery core part of the battery is jointly developed by SAIC-GM and CATL, and the design of the battery module to the whole package is responsible for the Pan-Asia Automotive Technology Center (hereinafter referred to as Pan-Asia). Fanya is an automotive design and development center jointly established by General Motors (China) and SAIC.

Saic General Motors and CATL are preparing to start mass production of the battery and plan to install it on a pure electric model next year. CATL will be responsible for the production of the battery cell, and the rest of the production and assembly of the battery pack will be completed by SAIC-GM's Autoneng Super factory.

Saic-gm has built two Ultratergy gigafactory plants in Shanghai and Wuhan. The plant produces core components such as batteries and electric drives based on Otteron electric vehicle platforms for SAIC GM's Buick, Chevrolet, and Cadillac brands.

Charging is as fast as refueling

Last year, CATL released the industry's first lithium iron phosphate 4C supercharged battery, and this year launched its upgraded version of Shenxing PLUS. The company launched several Tianxing batteries for commercial vehicles this year, and the 4C supercharge is also a major selling point.

Before the release of the Shenxing battery series, 4C fast-charging batteries were mainly ternary batteries, which had expensive problems. In the domestic market, ternary batteries are another power battery technology route second only to lithium iron phosphate, and a number of battery companies have launched ternary batteries that support 6C fast charge.

"Saic-gm said that the joint launch of 6C ultra-fast lithium iron phosphate battery technology with CATL not only sets a new technical benchmark for the industry, but also highlights SAIC-GM's forward-looking vision on the new energy track, and the excellent research and development strength of Pan-Asia Automotive Technology Center for continuous innovation." "In the future, SAIC-GM will continue to work with top industry partners to bring more intelligent, efficient and convenient new energy travel solutions to consumers and jointly promote the sustainable and healthy development of the new energy automobile industry."