Great Power Energy Technology Conference Launched Great Power Energy's First Generation of Solid-State Batteries

On August 28, Guangzhou Great Power Energy and Technology Co., Ltd (Great Power)held an online product technology conference and officially unveiled the solid-state battery veil. Released together with solid-state batteries, there are new low-temperature household storage batteries and new 590Ah large-capacity power storage batteries.

The low-temperature household storage battery released by Great Power has reached -30 ° C in low-temperature charging, the charging and discharging efficiency is more than 95%, and the cycle is more than 5000 times, compared with the product before iteration, the comprehensive performance has been improved. In terms of large-capacity cells, the large-capacity 590Ah wind Peng cell released by Great Power has made breakthroughs in power, energy efficiency, cycle and safety, and the power and energy efficiency performance is especially bright. According to the press conference, Great Power will increase the energy efficiency to 97% through self-developed ion sponge platform technology, and the battery loss will be greatly reduced. The power of this 590Ah large-capacity power cell will reach 2P, which is of great significance for the current energy storage frequency modulation function, and can match the current half-hour working conditions of the terminal market.

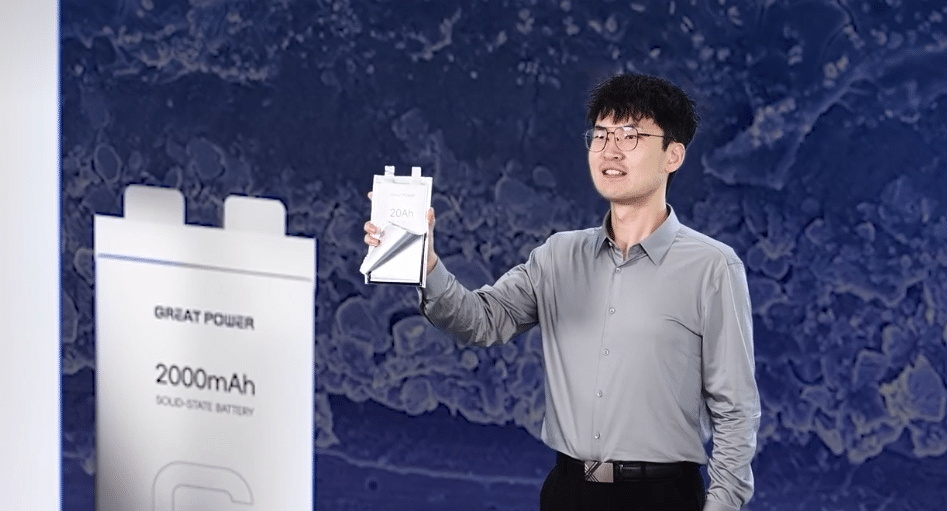

2000mAh all-solid state battery, the speaker showed the 20Ah all-solid state battery physical object at the press conference, and did a cross-section explanation.

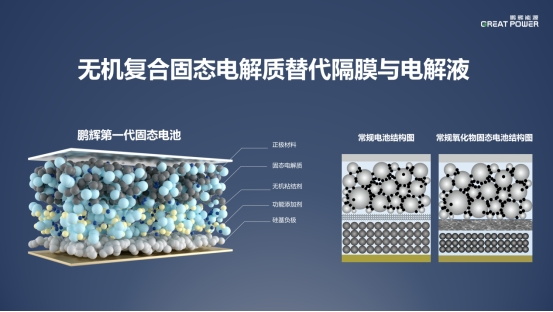

At the press conference, Great Power announced its all-solid-state battery technology route. Great Power uses oxide composite solid electrolyte to build all-solid-state batteries, realizing the essential safety of batteries, and greatly reducing the cost of solid-state batteries! Safety and cost reduction have become the core advantages of Great Power's first generation of solid-state batteries.

The preparation of oxide ceramic electrolyte materials in solid state batteries usually requires a high temperature sintering process, which is not only a high energy consumption, but also a low efficiency. In addition, the inherent brittleness of ceramics makes the preparation of high-capacity cells challenging. At the press conference, Great Power announced its two major breakthroughs in the field of solid state batteries: process innovation and material system optimization, which solved the technical problems of the oxide solid electrolyte process.

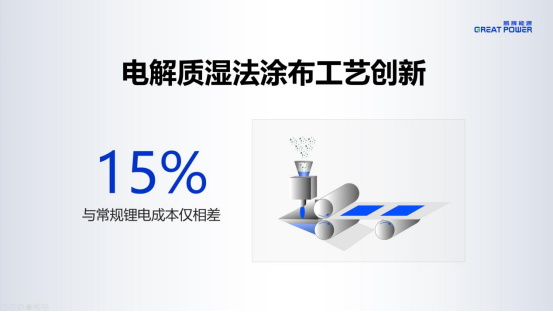

In terms of process innovation, Great Power independently developed a unique electrolyte wet coating process. This process successfully bypasses the high temperature sintering process of oxide solid electrolyte, avoids the inherent brittleness of ceramic materials, and greatly simplifies the process. The overall cost of solid-state batteries using this process is expected to be only about 15% higher than the cost of conventional lithium-ion batteries. In the next 3 to 5 years, with the continuous optimization and innovation of the process and the further reduction of the material cost, Great Power said that the cost of its solid-state batteries is expected to be the same as that of conventional lithium batteries, laying a solid foundation for the industrialization of the company's solid-state batteries.

In terms of material innovation, Great Power's solid-state battery uses a self-developed inorganic composite solid-state electrolyte layer. In addition to oxide electrolytes, this electrolyte layer combines key materials such as new inorganic composite binders and functional additives. This innovation effectively improves the fragile characteristics of the ceramic during bending, enhances the adhesion and plasticity of the electrolyte layer, and significantly reduces the probability of internal short circuit of the solid-state battery. At the same time, it also effectively improves the ionic conductivity of the inorganic composite electrolyte layer, reduces the internal resistance of the cell, and further improves the heat dissipation capacity and safety performance of the solid-state battery. Great Power has truly achieved a breakthrough of "more than electrolytes" through the self-developed inorganic composite solid electrolyte layer.

Great Power's all-solid-state batteries perform well in terms of safety performance and can pass the most demanding needle tests. Its non-combustible solid electrolyte combined with the "automatic safety mechanism" achieves the desired performance of solid-state batteries - intrinsically safe. In addition to cost reduction and safety improvement, Great Power's all-solid-state batteries have been able to work stably in a wide temperature range of -20 ° C to 85 ° C, with an energy density of 280Wh/kg, and by 2025, by using a higher proportion of silicon-based negative electrodes, the energy density is expected to reach more than 300Wh/kg. It is reported that Great Power plans to establish a pilot line of all-solid-state batteries in 2025, and build a formal production line in 2026.

Great Power has been engaged in battery research and development and manufacturing for 23 years, is a low-key, pragmatic industry "veteran" of the lithium battery industry, thanks to the founder's senior technical background, the release of the all-solid-state battery has a number of key technical breakthroughs. As for the plan for large-scale mass production in 2026, it is not an exaggeration in the industry, so let's wait and see.

It is understood that in 2011, Great Power has begun to lay out energy storage and aim at lithium iron phosphate technology, and launched the company's first energy storage product - 10Ah/20Ah lithium iron phosphate energy storage battery, is one of the earliest companies to launch lithium energy storage battery. In 2019, Great Power launched 6C fast-charging power batteries, began to lay out sodium-ion battery technology, and piloted energy storage containers in Zhuhai Industrial Park.

Great Power is one of the first companies to pass the sodium-ion battery standard in China. In 2023, Great Power sodium ion battery energy density reached 150wh/kg, cycle life exceeded 6000 times, its sodium ion research and development and industrialization are in the forefront of the industry, and the current research on sodium electricity is also constantly moving forward.