SUNGROW PowerTitan Series Energy Storage Cabinets Complete Extreme Combustion Testing

In June 2024, Sungrow Power Supply actively initiated the combustion test of a PowerTitan 1.0 unit, announcing the completion of the world’s first large-scale combustion test for an energy storage system. In November of the same year, the company invested an additional 30 million yuan to conduct the largest and longest-duration live combustion test for the PowerTitan 2.0 (PT2.0) system, with a 20MWh capacity. Behind these two extreme live tests within six months is the company’s commitment to leading technological innovation, pursuing the highest standards of product quality, ensuring the safety of power station personnel and assets, and safeguarding the safety baseline of the energy storage industry.

The test was conducted under the supervision of DNV, the Norwegian classification society, and witnessed by over 100 global customers, strictly simulating a real-world power station fire scenario. The results showed that thermal runaway did not spread. Compared to conventional combustion tests in the industry, this test involved significantly upgraded test durations, conditions, and safety standards, achieving ultimate safety through extreme testing.

Challenge 1: 25-Hour Continuous Combustion to Verify the System’s Extreme Protective Ability

Unlike the industry’s typical 4-8 hour combustion tests, this test lasted 3-6 times longer. After 25 hours and 43 minutes of continuous combustion, the structure of the system’s individual cabinet remained intact, and it could still be lifted as a whole. The fire did not spread beyond the unit, demonstrating the PT2.0’s explosion-proof design, flame-retardant capabilities, and shock resistance.

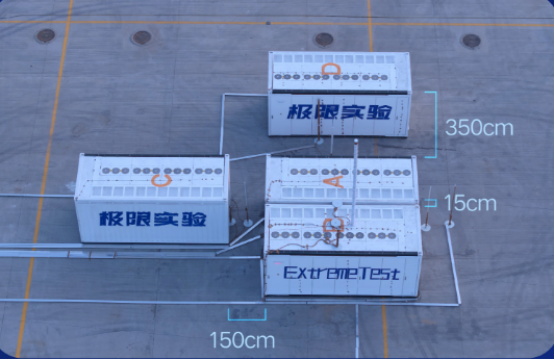

Challenge 2: Extreme High Temperatures Capable of Melting Steel, Verifying No Fire Spread During Thermal Runaway

In this test, four energy storage cabinets were fully charged to 100% capacity. Cabinets A and B were placed just 15 cm apart, a distance that exceeds typical industry practices (where cabinets in actual power stations are often spaced 3 meters apart). The test results showed that, despite the flames from thermal runaway in Cabinet A reaching 1385°C—sufficient to melt steel—the fire did not spread to the adjacent Cabinet B, which maintained a temperature of 40°C within normal operating range. This demonstrated the PT2.0’s excellent fireproof insulation capability, even in extreme proximity.

Challenge 3: Fire Resistance Without Fire Suppression Systems, Verifying the System’s Passive Fire-Resistant Performance

During the test, all fire suppression systems were intentionally disabled, placing the cabinets in a "bare" state with significantly increased safety risks. However, the PT2.0’s passive fire protection design ensured that none of the doors of the four storage cabinets were burned through, and the spread of the fire and the extent of the damage were minimized. This showcased the energy storage system’s powerful autonomous response capability in the face of extreme fire scenarios.

Safety is an unwavering bottom line in the energy storage industry. Sungrow’s continuous investment in extreme combustion testing for the PowerTitan series energy storage cabinets demonstrates its commitment to protecting power station personnel, assets, and operational safety, and fortifying the safety barriers of the energy storage industry. The success of this high-difficulty, high-standard combustion test provides empirical evidence for safety standards at the power station control level and sets a new benchmark for safety in the energy storage industry.