How to Match LiFePO4 Battery When DIY Battery Pack?

When DIYing a LiFePO4 battery pack, it is essential to properly match the individual cells to ensure performance consistency. Here’s how to choose and match the right LiFePO4 cells for your DIY battery pack.

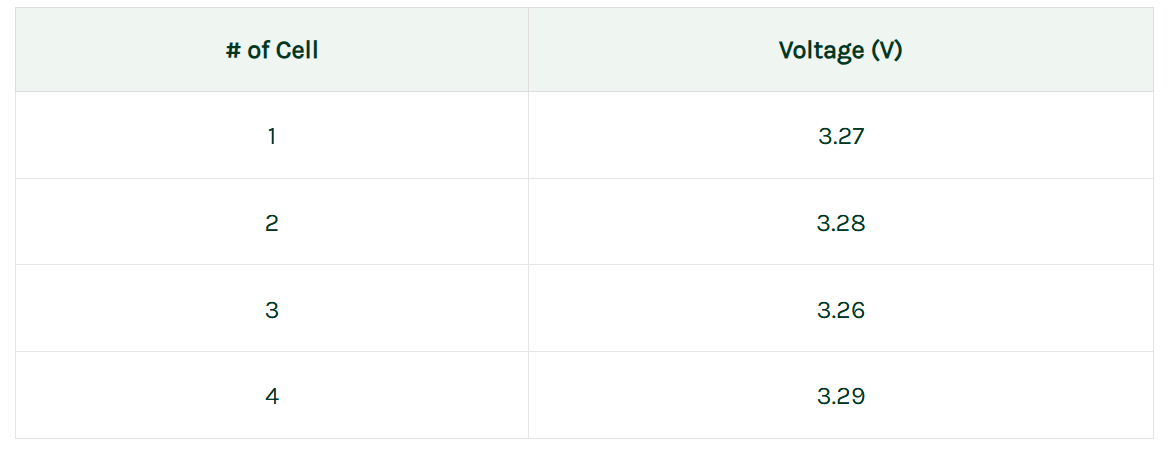

Matching the Voltage of LiFePO4 Cells

Within the same battery pack, voltage matching ensures similar voltage characteristics between the cells. This helps maintain a balanced voltage during charging and discharging.

Common voltage tolerance for LiFePO4 cells is ±0.05V to ensure a balanced voltage distribution within the battery pack. The battery pack should be equipped with a Battery Management System (BMS) to adjust voltage levels as needed. If the voltage difference between cells is too large, the BMS will have limited adjustment capability, which can lead to overloading of certain cells.

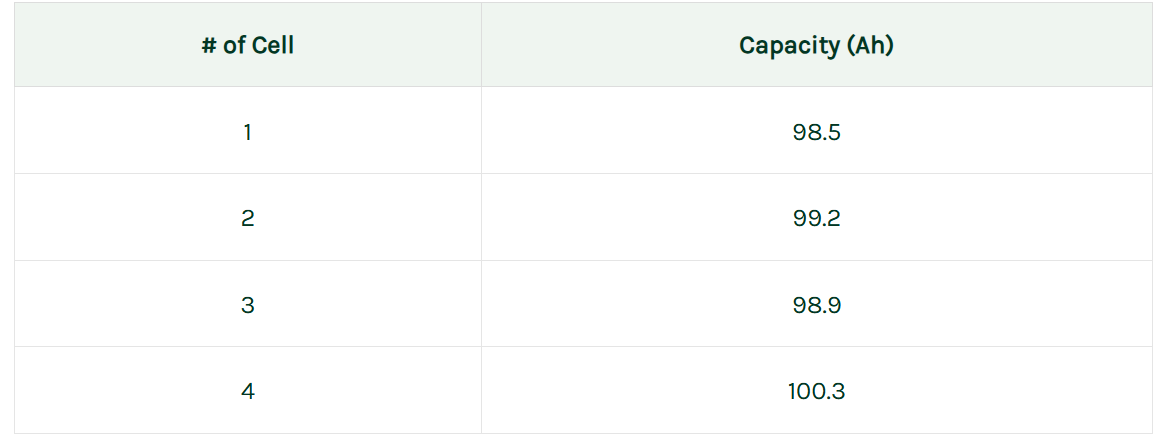

Matching the Capacity of LiFePO4 Cells

Capacity matching is critical to achieving the desired energy storage and discharge capabilities for the entire battery pack. Use cells with similar capacities to ensure the pack’s overall capacity meets your energy needs.

Before assembling the battery pack, set the desired capacity for the battery. Conduct charging/discharging tests to confirm the capacity of individual cells and match them accordingly. Define an acceptable capacity tolerance, generally ±5%, to maintain consistent performance.

Matching the Internal Resistance of LiFePO4 Cells

Internal resistance matching ensures that current is evenly distributed across the cells during charging and discharging. Large internal resistance differences can lead to overheating, reduce the lifespan of the battery pack, and pose safety risks.

Measure the internal resistance using methods such as electrochemical impedance spectroscopy or constant current discharge tests to ensure consistency across the cells. Define an internal resistance tolerance of around ±5%.

Temperature Control

Keep the temperature within the 15-30°C range during the assembly process. Use temperature sensors to monitor the environmental temperature and implement cooling measures if necessary.

Battery Management System (BMS) Monitoring

The BMS is responsible for balancing the charging and discharging process, monitoring the voltage, capacity, and temperature of each cell, and making adjustments as needed.

Charging Process

During charging, the BMS adjusts the charging current or employs active balancing technology to ensure all cells are charged evenly.

Discharging Process

During discharge, the BMS monitors the voltage and capacity of each cell, adjusts the load when necessary, or uses active balancing technology to maintain cell consistency.

In conclusion, when DIYing a LiFePO4 battery pack, ensure the cells are properly matched in terms of voltage, capacity, and internal resistance, while also managing temperature and setting up the BMS. We also recommend using cells from the same production batch or cells with similar manufacturing parameters, which will greatly improve performance consistency.

Properly matching LiFePO4 cells is crucial for building a high-performance, safe DIY battery pack. Taking the time to carefully match the performance characteristics of the cells will help ensure your custom LiFePO4 battery pack operates optimally for years to come.