EVE Energy presents comprehensive solutions for construction machinery at Bauma 2024

From November 26 to 29, 2024, Bauma China 2024 was grandly opened at the Shanghai New International Expo Centre. As a global leader in lithium battery manufacturing, EVE Energy showcased its comprehensive electrification solutions for construction machinery and made a major announcement of its new open-source battery system. This new innovation aims to reduce costs and improve efficiency in the new energy construction machinery industry, ushering in a new era of operational transformation.

Leading Innovation in Commercial Vehicle Battery Technology to Drive Industry Electrification

Since 2015, EVE Energy has been a pioneer in advancing electrification for commercial vehicles and construction machinery. Its products now cover 14 countries worldwide and have withstood extreme temperature tests, serving over 80% of leading domestic clients. At Bauma China, EVE Energy presented its complete battery system solutions tailored for the construction machinery sector, demonstrating its technological expertise and commitment to the industry’s electrification transformation.

Zheng Feng, Director of EVE Energy’s Battery System Research Institute, introduced the company’s comprehensive electrification solutions designed for construction machinery applications. The solution covers four core areas: construction machinery, heavy-duty trucks, aerial work platforms, and specialty machines, incorporating four key advantages of the open-source battery: faster charging, higher structural strength, longer range, and greater safety. These battery systems significantly improve operational efficiency and reliability, addressing challenges in high-load, full-coverage, and full-lifecycle operations.

Advanced Technologies Empowering Electrification in Construction Machinery

At the event, EVE Energy engaged in in-depth discussions with global construction machinery manufacturers such as Caterpillar, XCMG, SANY, Zoomlion, and Liugong, exploring industry trends, application requirements, and future product directions. EVE Energy also showcased several innovative battery products and solutions, underscoring its deep technical capabilities in the electrification of construction machinery.

The B3P Platform is an innovative battery system designed by EVE Energy for construction vehicles. It utilizes dual-liquid cooling technology, ensuring stable operation across all temperature ranges while delivering ultra-high strength and long lifespan. This platform meets the power needs of traditional loaders and mining trucks, offering battery solutions ranging from 114kWh to 700kWh.

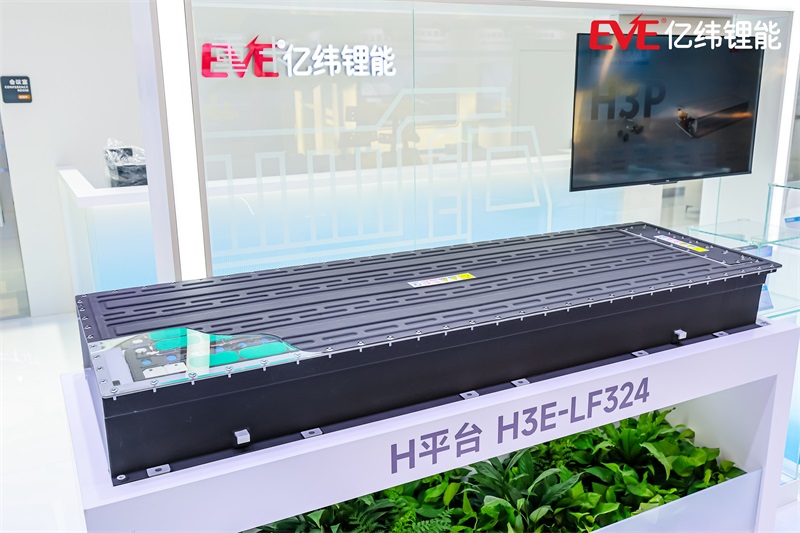

For the heavy-duty truck and mining truck sectors, EVE Energy introduced the H3E Platform, featuring the CTP (Cell to Pack) module-free design and full foam technology, which significantly enhance the packaging efficiency and structural strength of the battery system. This battery supports multiple charging modes, including rear and side charging, with a unique dual-station, four-gun charging technology that boosts charging efficiency, reduces charging time, and improves the operational efficiency of large-capacity trucks and mining vehicles.

For aerial work platforms, EVE Energy launched the ES Series Platform battery system. This series integrates the BDU (Battery Disconnect Unit), reducing design costs while improving system reliability and space utilization. These batteries are suitable for a full range of scissor lifts, from 6 meters to 14 meters, meeting high-efficiency operation needs across different working conditions.

Focusing on the Future: Accelerating Electrification Transformation

Looking ahead, EVE Energy will continue to adhere to its corporate philosophy of “Integrity in Business, Innovation for the Future,” focusing on the key demands and challenges of the construction machinery industry. Driven by technological innovation, the company will work closely with industry partners to accelerate the electrification transformation of construction machinery. EVE Energy’s advanced battery systems will continue to support the widespread adoption and development of new energy construction machinery, contributing to a greener, smarter, and more efficient future for the industry.

Through its participation in Bauma China 2024, EVE Energy has showcased its innovative achievements in the electrification of construction machinery and provided robust technological support and solutions for the industry's future development.