Lithium Titanate LTO Batteries: With Remarkable Advantages, Poised to Become the Next-Generation Lithium-Ion Battery Material

Lithium Titanate LTO Battery, as a negative electrode material for lithium-ion batteries, can be combined with manganate lithium, ternary materials, or phosphate lithium as positive electrode materials to form a lithium-ion secondary battery with a voltage of 2.4V or 1.9V. In addition, it can also be used as the positive electrode, combined with the negative electrode of metal lithium or lithium alloy to form a lithium secondary battery with a voltage of 1.5V. Due to the high safety, stability, long life, and green environmental protection features of titanate lithium, it is expected that titanate lithium materials will become the next-generation negative electrode material for lithium-ion batteries and be widely used in new energy vehicles, electric motorcycles, and applications requiring high safety, stability, and long-term use within 2-3 years. The working voltage of titanate lithium batteries is 2.4V, the maximum voltage is 3.0V, and the charging current can reach up to 2C.

The Composition of Lithium Titanate LTO Battery

Positive Electrode: Phosphate lithium, manganate lithium, or ternary materials, nickel manganate lithium.

Negative Electrode: Titanate lithium material.

Separator: Carbon-based negative electrode lithium battery separator.

Electrolyte: Carbon-based negative electrode lithium battery electrolyte.

Battery Case: Carbon-based negative electrode lithium battery case. To meet the requirements of electric vehicles for onboard lithium-ion battery packs, developing safe, high-rate performance and long-life negative electrode materials is a hotspot and a challenge.

Advantages of Lithium Titanate LTO Battery

The use of electric vehicles to replace fuel vehicles is the best choice to solve urban environmental pollution, among which lithium-ion power batteries have attracted wide attention from researchers. In order to meet the requirements of electric vehicles for on-board ion power batteries, it is a hot and difficult point to develop negative electrode materials with high safety, good rate performance, and long life.

At present, commercial lithium-ion battery negative electrodes mainly use carbon materials, but there are some disadvantages in the application of lithium batteries with carbon as the negative electrode:

1. Overcharging may cause lithium dendrites to precipitate, leading to battery short circuits and affecting the safety performance of lithium batteries;

2. It is easy to form SEI film, resulting in low first charge and discharge efficiency and large irreversible capacity;

3. The platform voltage of carbon material is low (close to metallic lithium), and it is easy to cause electrolyte decomposition, thus bringing about safety hazards.

4. The volume changes greatly during the insertion and extraction of lithium ions, resulting in poor cycle stability.

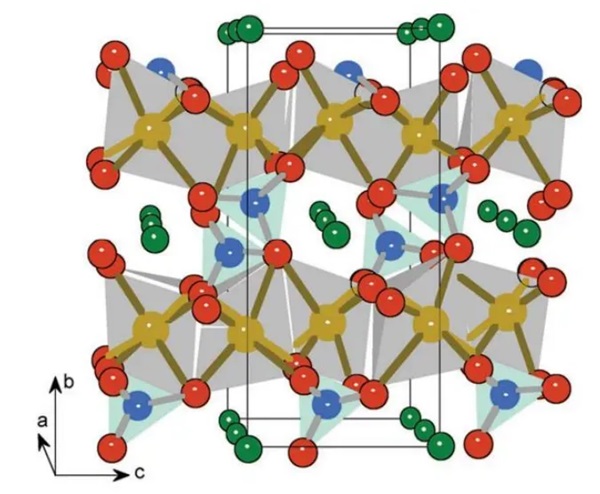

Compared with carbon materials, the Li4Ti5012 spinel-type material has obvious advantages:

1. It is a zero-strain material with good cycling performance;

2. The discharge voltage is stable, and the electrolyte does not decompose, improving the safety performance of lithium batteries;

3. Compared with carbon-negative electrode materials, titanium dioxide has a high lithium ion diffusion coefficient (2*10-8cm2/s) and can be charged and discharged at high rates.

4. The potential of titanium dioxide is higher than that of pure metallic lithium, and it is less prone to lithium dendrite precipitation, providing a basis for ensuring the safety of lithium batteries.

The domestic and foreign application trends of titanium dioxide batteries A Japanese company, Scib, produces lithium-ion batteries with titanate lithium as the anode, which have been mass-produced and applied to the "EVneo" electric motorcycles.

Guangzhou Yintong New Energy Co., Ltd. in Zhuhai, China, began mass-producing lithium titanate lto battery for energy storage in late 2009, and in November 2010, it acquired a 51% controlling stake in American NASDAQ-listed company ALTI, the world leader in lithium titanate technology, for 325 million yuan. Just one year earlier, the Chinese company had entered the battery business, and it has now acquired a US company to boost its technological capabilities. This can be seen as a direct expression of the aggressive momentum of Chinese companies today. It marks the first cross-border acquisition in China's battery industry.